Tuesday, 21 March 2017

Both waterborne and oil based polyurethane finishes have their particularities. Despite what many people believe, a waterborne finish is, on a long-term basis, more resistant than the oil based finish.

Waterborne polyurethane finishes

They offer a large quality and durability range. To have a high quality finish, make sure you choose a product that mostly contains urethane and not acrylic resins. Due to their complex molecular structures, the waterborne formulations offer major benefits: better abrasion resistance, greater substrate adherence, better flexibility and higher contaminant resistance.

Unlike the oil based polyurethanes, the luster level of the waterborne finishes do not affect their long-term durability. For example, a matte luster (10%) is as resistant as a high-gloss luster (90%). They produce no odor and have no negative effects on the home owner’s health. They can therefore stay home upon application and there is no need of emptying the pantry!

When applied, they form a thinner layer of product on the surface, but that do not compromise their long-term durability. The reason behind the thickness difference between the waterborne finish and the oil based finish is simply the difference between the solid material quantity that can contain the water (30%) and the oil (50%). Therefore, the quantity of solid material in an oil based finish is approximately twice as high as in a waterborne finish.

However, the waterborne polyurethane has a tendency of being less resistant to calcium, such as the snow on boots during winter time. It is therefore recommended to protect your floors with a carpet near the entrance doors. If your floors are already damaged by calcium, it is important to properly prepare the surface before the finish application with a cleaning product that is recommended for your type of floor.

Oil based polyurethane finishes

Usually called Varathane, they are often chosen because they are economic, easily applicable and easy to use on wooden floors. However, the strong smell they release strain the residents to leave their house upon application.

The long-term durability of these finishes also tends to be a weakness. Having a very low scratch-resistance, the restoration has to be done more frequently.

Moreover, upon application, the oil based finishes already has a yellowish tint that tends to amplify a lot as time goes by. The trend being to pale flooring, it can represents a significant disadvantage of this type of finish.

They also are environmentally and healthily harmful products. A Canadian government norm, effective since 2010, regulates the maximal VOC (Volatile Organic Compound) rate that can be found in finishes that are sold in gallon. Since the oil based polyurethane finishes exceed that rate, the manufacturers are forced to sell their product in a pint format, which can be annoying when you have a large surface to finish.

We hope those informations have enlightened you on which polyurethane finish to choose depending on the project that you have to complete. If you have questions for which we couldn’t give an answer here, feel free to contact our expert team that will be able to guide you through your project.

To discover the Finitec Expert polyurethane finishes line, you can visit the following page: www.finitecexpert.com

Finitec 3000

Finitec 3000 Finitec 6000

Finitec 6000 Finitec 9000

Finitec 9000 Finitec Recoater

Finitec Recoater Finitec Synergy

Finitec Synergy Microban antimicrobial finish

Microban antimicrobial finish Solidex

Solidex Finitec 3000

Finitec 3000 Finitec 6000

Finitec 6000 Finitec Recoater

Finitec Recoater Finitec Synergy

Finitec Synergy Microban antimicrobial finish

Microban antimicrobial finish Surface Preparation

Surface Preparation Water based stain

Water based stain Woodfloor Finish Dye

Woodfloor Finish Dye Applicator refills

Applicator refills Finish applicator

Finish applicator Finitec Sanding Machine

Finitec Sanding Machine Complete care system for wood and laminate floors

Complete care system for wood and laminate floors Laminate wood floral breeze floor cleaner 3.78L

Laminate wood floral breeze floor cleaner 3.78L Laminate wood mint floor cleaner 3.78L

Laminate wood mint floor cleaner 3.78L Ultra concentrated cleaner for wood and laminate floor maintenance

Ultra concentrated cleaner for wood and laminate floor maintenance Wood and laminate floor cleaner

Wood and laminate floor cleaner Ceramic joints cleaner

Ceramic joints cleaner Cleaner for ceramic floors

Cleaner for ceramic floors Complete care system for ceramic joints

Complete care system for ceramic joints Ultra concentrated cleaner for ceramic floors

Ultra concentrated cleaner for ceramic floors Ceramic joints cleaning brush

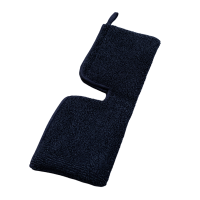

Ceramic joints cleaning brush Reversible replacement mop cover

Reversible replacement mop cover Velcro replacement mop cover

Velcro replacement mop cover Age-Tech

Age-Tech Tonic vinyl, ceramic, wood and laminates floors

Tonic vinyl, ceramic, wood and laminates floors Wood glue

Wood glue DESIGN Paint

DESIGN Paint Flush mount

Flush mount Top mount

Top mount MicroConcrete

MicroConcrete MicroConcrete filling

MicroConcrete filling MicroConcrete sealer

MicroConcrete sealer MicroConcrete Flexible Trowel

MicroConcrete Flexible Trowel 17 in Pad_thick

17 in Pad_thick 17 in Pad_thin

17 in Pad_thin Ceramic abrasive belt

Ceramic abrasive belt Ceramic edger disc

Ceramic edger disc PSA adhesive roll

PSA adhesive roll Zirconium abrasive belt

Zirconium abrasive belt Zirconium edger disc

Zirconium edger disc EX-1

EX-1 EX-3

EX-3 EX-6

EX-6 EX-DUO+

EX-DUO+ EX-HYBRID

EX-HYBRID EX-TECH

EX-TECH EX-PRIME

EX-PRIME Finish dye

Finish dye Finish applicator

Finish applicator Finish applicator (T-bar)

Finish applicator (T-bar) Replacement finish applicator (T-bar)

Replacement finish applicator (T-bar) Replacement pad finish applicator

Replacement pad finish applicator Wood glue

Wood glue Wood patch

Wood patch EXTRA+

EXTRA+ SURFACE Treatment

SURFACE Treatment SURFACE Care

SURFACE Care DESIGN paint / SURFACE Color

DESIGN paint / SURFACE Color PROFLEX SURFACE sealer

PROFLEX SURFACE sealer SURFACE Sealer

SURFACE Sealer TOP SURFACE finish

TOP SURFACE finish Industrial lacquer

Industrial lacquer