Wednesday, 22 November 2017

That’s a question you may have asked but the explanation is not always as simple as it sounds.

In this article, we’ll try to demystify two-component finishes by considering its components, strengths and weaknesses.

First lets address exactly what a two-component finish consists of. Yes you guessed right there are 2 necessary elements. Part A is a water based polyurethane, and Part B consists of a catalyst or crosslinking agent.

Catalysts are used in a variety of different applications, but in the waterbased finish industry the 2 most popular are isocyanate and aziridine. What are the differences?

Isocyanate are a family of highly reactive, very toxic chemicals which when combined with polyurethane act as a hardener. Once added to the finish there is a 3-4 hour open time to apply the coating. After that the isocyanate starts to congeal the finish making it impossible to work with. The remaining catalyzed finish is no longer of any value.

The Aziridine is an organic chemical compound which is designed to provide superior durability and chemical resistance. While still toxic and requires proper care when working with it, this product is less toxic than its predecessor. Once added to the finish, the catalyst is active for 12 hours, after which the effectiveness of the catalyst is no longer remains, yet the product remains liquid and with care could even be re-catalyzed. There is no loss of product when Aziridine is used as the catalyst.

Finitec offers in the Finitec Expert program a two-component water based polyurathane called Ex-Duo which uses aziridine as its catalyst. But unlike other water based finish manufactures the full line of Finitec Expert finishes can be catalysed to enhance their performance.

But why choose a two-component over a single-component finish?

When incorporating the catalyst in the finish we accelerate the cure, and improve the finishes ability to resist water, abrasion and chemical products.

Hope this article helped answer your question.

If you have any questions or concerns regarding two-component finishes, please feel free to contact Jeff Cowx Finitec s coating specialist at jcowx@finitec-inc.com

Finitec 3000

Finitec 3000 Finitec 6000

Finitec 6000 Finitec 9000

Finitec 9000 Finitec Recoater

Finitec Recoater Finitec Synergy

Finitec Synergy Microban antimicrobial finish

Microban antimicrobial finish Solidex

Solidex Finitec 3000

Finitec 3000 Finitec 6000

Finitec 6000 Finitec Recoater

Finitec Recoater Finitec Synergy

Finitec Synergy Microban antimicrobial finish

Microban antimicrobial finish Surface Preparation

Surface Preparation Water based stain

Water based stain Woodfloor Finish Dye

Woodfloor Finish Dye Applicator refills

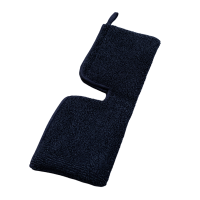

Applicator refills Finish applicator

Finish applicator Finitec Sanding Machine

Finitec Sanding Machine Complete care system for wood and laminate floors

Complete care system for wood and laminate floors Laminate wood floral breeze floor cleaner 3.78L

Laminate wood floral breeze floor cleaner 3.78L Laminate wood mint floor cleaner 3.78L

Laminate wood mint floor cleaner 3.78L Ultra concentrated cleaner for wood and laminate floor maintenance

Ultra concentrated cleaner for wood and laminate floor maintenance Wood and laminate floor cleaner

Wood and laminate floor cleaner Ceramic joints cleaner

Ceramic joints cleaner Cleaner for ceramic floors

Cleaner for ceramic floors Complete care system for ceramic joints

Complete care system for ceramic joints Ultra concentrated cleaner for ceramic floors

Ultra concentrated cleaner for ceramic floors Ceramic joints cleaning brush

Ceramic joints cleaning brush Reversible replacement mop cover

Reversible replacement mop cover Velcro replacement mop cover

Velcro replacement mop cover Age-Tech

Age-Tech Tonic vinyl, ceramic, wood and laminates floors

Tonic vinyl, ceramic, wood and laminates floors Wood glue

Wood glue DESIGN Paint

DESIGN Paint Flush mount

Flush mount Top mount

Top mount MicroConcrete

MicroConcrete MicroConcrete filling

MicroConcrete filling MicroConcrete sealer

MicroConcrete sealer MicroConcrete Flexible Trowel

MicroConcrete Flexible Trowel 17 in Pad_thick

17 in Pad_thick 17 in Pad_thin

17 in Pad_thin Ceramic abrasive belt

Ceramic abrasive belt Ceramic edger disc

Ceramic edger disc PSA adhesive roll

PSA adhesive roll Zirconium abrasive belt

Zirconium abrasive belt Zirconium edger disc

Zirconium edger disc EX-1

EX-1 EX-3

EX-3 EX-6

EX-6 EX-DUO+

EX-DUO+ EX-HYBRID

EX-HYBRID EX-TECH

EX-TECH EX-PRIME

EX-PRIME Finish dye

Finish dye Finish applicator

Finish applicator Finish applicator (T-bar)

Finish applicator (T-bar) Replacement finish applicator (T-bar)

Replacement finish applicator (T-bar) Replacement pad finish applicator

Replacement pad finish applicator Wood glue

Wood glue Wood patch

Wood patch EXTRA+

EXTRA+ SURFACE Treatment

SURFACE Treatment SURFACE Care

SURFACE Care DESIGN paint / SURFACE Color

DESIGN paint / SURFACE Color PROFLEX SURFACE sealer

PROFLEX SURFACE sealer SURFACE Sealer

SURFACE Sealer TOP SURFACE finish

TOP SURFACE finish Industrial lacquer

Industrial lacquer